Steel Multi-flue Chimney Inspections & Repairs

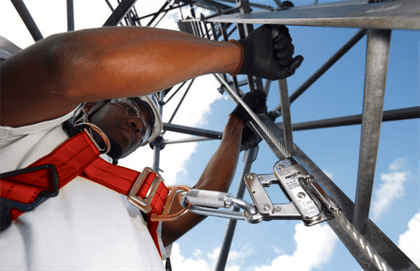

Horizon recently completed the inspections and repairs of two 25 metre steel multi-flue chimneys, at a site in the South West of the UK.

The initial inspection revealed varying degrees of defect, for instance one of the flue arms was discharging effluent product directly onto the flues and causing staining. It was imperative this defect was addressed, as it would ultimately result in the deteriorating and holing to the cladding.

In line with the recommendations of the ATLAS guidelines for steel chimneys, it is advocated that every 4 years 2 No. bolts are removed from the flange and are microscopically assessed to determine if any defects are present within the bolts. Bolts should then be tested for ultimate tensile failure for comparison against rated value of new bolts.

The Lightning Protection System on the chimney was also tested at the time of the inspection, and it was found the earth impedance readings obtained at each position exceeded the maximum recommended (20.0 ohms) permissible, in accordance with the guidelines of BS 6651:1999. Therefore, in order to meet the requirements of the British Standard guidelines it was recommended that the earths were upgraded using earth mats with the aid of soil conditioning agent.

In order to ensure both the generator and boiler chimney structures were compliant, and in good working order a programme of remedial works were undertaken by Horizon in line with our recommendations. This was completed on time and to budget.